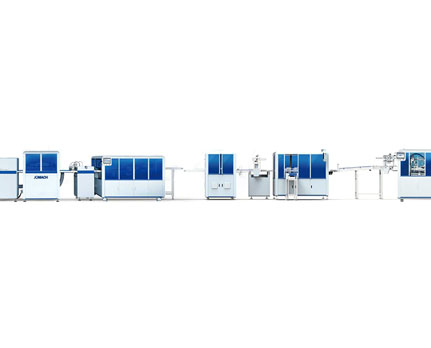

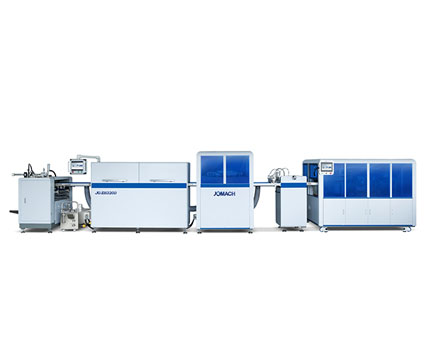

With the development of automation technology and the increase in labor costs, many manufacturing companies have to choose slip case making machine in order to improve production efficiency and save labor costs. Slip case making machine has a high degree of automation, fast speed, and does not require manual intervention. Fully automated operations are widely used in wine boxes, gift boxes, digital home appliances, and other industries. This article will tell you how to debug the slip case making machine.

1. Check the working status of the equipment

Before adjusting the slip case making machine, you need to check the working status of the equipment. The operator needs to confirm whether the power supply of the equipment is normal, whether all parts are firmly connected, and whether each button is sensitive. Only after checking that the equipment is in normal working condition can subsequent adjustment work be carried out.

2. Adjust the mold

The mold of the slip case-making machine is the key to determining the molding quality. During the machine adjustment process, the mold needs to be carefully adjusted to ensure the stability of the gift box molding quality. The specific steps are as follows:

1. Check the installation status of the mold to ensure that the mold is not loose or swinging.

2. Clean the mold to ensure that no residue disturbs the molding process.

3. Adjust the height and level of the mold to ensure mold pressure balance and stable molding quality.

3. Adjust pressure

During the adjustment process of the slip case making machine, the pressure needs to be continuously adjusted. The specific steps are as follows:

1. Adjust the air pressure value to ensure that the air pressure is stable and will not affect the molding process.

2. Adjust the pressure of the press to ensure that the pressure for forming the gift box is stable and will not be too loose or too tight.

4. Adjust the inlet and outlet material levels

The inlet and outlet material level is a very critical part of the slip case making machine forming process. When adjusting the machine, it is necessary to make different adjustments to the inlet and outlet material levels according to different production needs.

1. Adjust the inlet and outlet material levels as required to ensure smooth transportation of raw materials.

2. According to the needs of the product, further adjust the inlet and outlet material levels to ensure that the product quality meets the requirements.

【Summarize】how to debug the slip case making machine

1. Check the working status of the slip case making machine equipment

2.Check the installation status of the mold to ensure that the mold is not loose or swinging.

3.Adjust the height and level of the mold to ensure mold pressure balance and stable molding quality.

4.Adjust the inlet and outlet material levels as required to ensure smooth transportation of raw materials.

5.According to the needs of the product, further adjust the inlet and outlet material levels to ensure that the product quality meets the requirements.

The above is an introduction to the adjustment techniques of the slip case making machine. Machine adjustment is an important operation step of the gift box forming machine, which requires the operator to have rich operating experience and professional skills. I hope this article can help operators better use the slip case making machine and improve the quality and production efficiency of gift box molding.