When selecting a high-quality rigid box making machine, understanding its features and functions is crucial for ensuring it meets production needs and delivers consistent performance. Here’s a concise overview of the key aspects to consider.

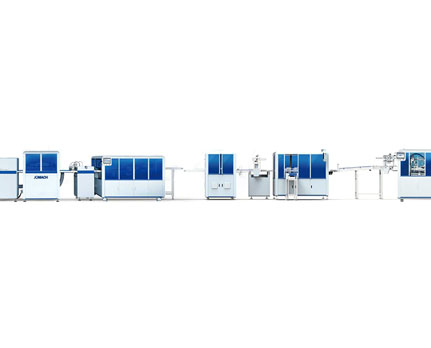

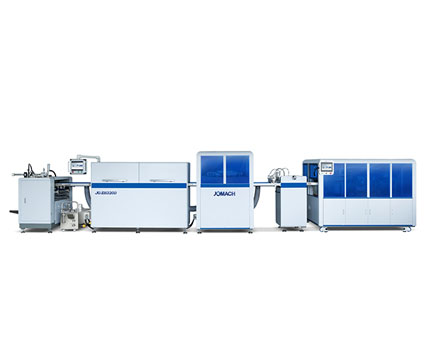

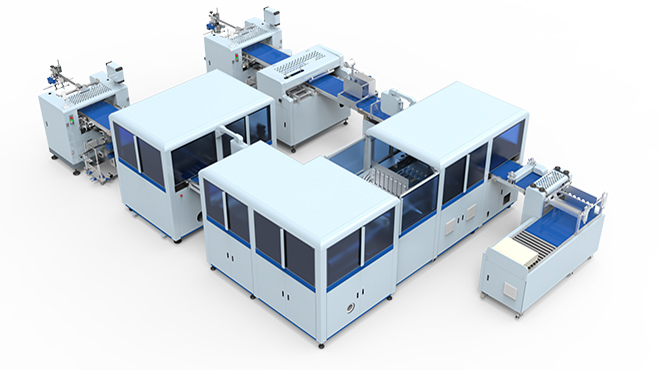

1.rigid box making machine Features

Production Speed: Measures how many boxes the machine can produce per hour.

Size Versatility: Capable of handling various box sizes and styles.

Build Quality: Made from durable materials like high-strength steel or aluminum.

Key Components: Includes high-quality motors, gears, and bearings.

Automation Level: Features automated feeding, folding, gluing, and stacking.

2.rigid box making machine Functions

Precision Cutting and Folding: Ensures accurate box dimensions and high-quality finishes.

Material Efficiency: Optimizes cutting patterns to minimize waste.

Energy Efficiency: Incorporates technologies to reduce power consumption.

Ease of Maintenance: Designed for straightforward cleaning and repairs.

Safety Features: Equipped with protective guards and emergency stop functions.

Conclusion:

By focusing on these essential features and functions, you can make an informed decision and choose a machine that enhances production efficiency, maintains high-quality standards, and offers long-term rigid box making machine.