Automatic Drawer Box Making Machine suitable for perfume and other cosmetics, mobile phones and other electronic products, sweets, electronic cigarettes gifts and other high-end box packaging.

Compared with the traditional box-type process, paper and board can be saved by 20% - 50%, with high cost performance.

Compared with the traditional box type, the box seams are reduced from 4 to 1, with more nice.

|

Machinery Name |

Automatic Drawer Box Making Machine |

Bubble Press Machine |

|

Machinery Model |

JG-CT200A |

JG-YP200 |

|

Max. Paper Size |

350×660mm(L×W) With Bottom Paper |

|

|

Min. Paper Size |

100×260mm(L×W) |

|

|

Min. Box Size |

L60×W25×H80mm |

L60×W25×H80mm |

|

Max. Box Size |

L160×W140×H200mm |

L160×W140×H200mm |

|

Paper thickness |

157-275gsm |

|

|

Cardboard thickness |

1.0-3.0mm |

|

|

Precision |

±0.15mm |

|

|

Speed |

18-25 pcs/min |

25 pcs/min |

|

Machine power |

18Kw |

3Kw |

|

Heating power |

9 kw |

|

|

Machine dimension |

L7300×W2000×H2000mm |

L2700×W1520×H1750mm |

|

Machine weight |

5200kg |

1200kg |

Remark:

1.The Max. and Min. size of the boxes are subjected to the sizes and quality of the paper;

2.The speed of the machine depends on the box sizes and the material and quality of paper and board;

Sample:

Tags:Slipcase Making Machine,Slip Case Making Machine,Sleeve Box Making Machine,Automatic Slipcase Box Making Machine,Cell Phone Box Making Machine,Mobile Box Making Machine,Perfume Box Making Machine,Drawer Box Making Machine

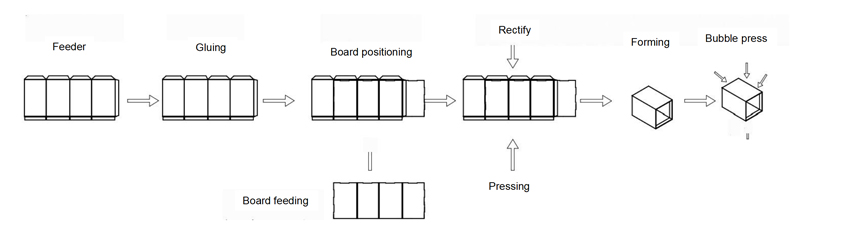

1.Feeder Part:Servo-driven mechanical structure to ensure paper feeding stability and paper feeding speed; |

|

2.Robot locating:Adopt 20 million pixel visual positioning and gantry manipulator grasping system, to ensure ±0.15mm positioning accuracy and 18-25 pcs/min speed. |

|

3.Rectification Part:Before the paper enters the forming part, adjust the position to ensure a firmer wrapping. |

|

4.Servo Wrapping Part:The box forming mechanism is upgraded to servo drive, which is faster, more stable and easier to adjust. |

|

5.Bubble Press Part:Grasping is more stable, adopt five side pressing and pushing form for box-out, so that the bubble pressing time is longer and the overall speed is faster. |

|

GET A QUOTE

export@86jg.com