Automatic Rigid Box Making Machine JG-FMLD780 is suitable for all kinds of paper hardcover wrapping, lining,ribbon and iron sheet integrated production.

Using 20-megapixel visual positioning + gantry manipulator grasp system positioning which is efficient and accurate.

The whole machine adopts servo motion control and adjustment,intelligent industrial control system; to realize the production and size parameter setting.The operation is simple,which product size data can be input with one click, and the servo motors of each unit can quickly move and adjust to complete plate replacement.

The original cam transmission structure makes purely mechanical edge wrapping fast and stable.The high-efficiency transmission ensures tight edge wrapping and beautiful wrapping corners.

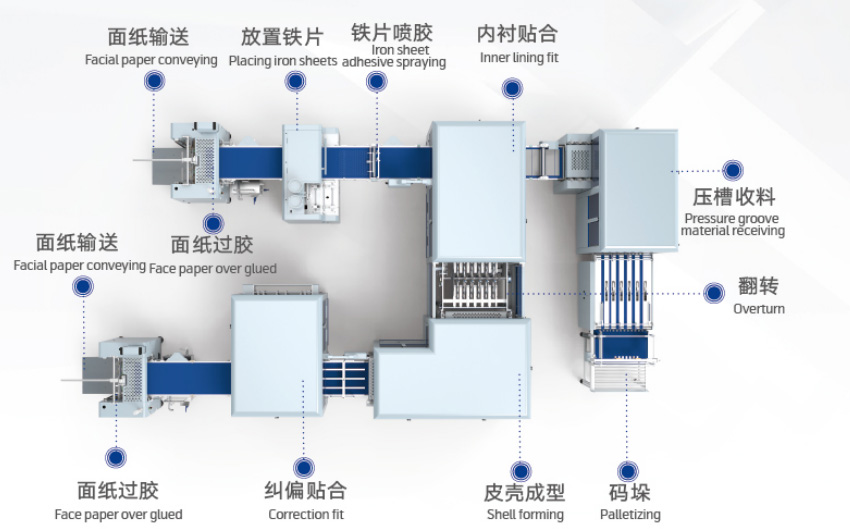

The intelligent human-machine interface system realizes automatic paper feeding,gluing,positioning, correction, folding, corner wrapping,and stacking in one go.

Suitable for the production of high-end hard cover, slip box prod-ucts,such as: wine box, cigarette box, books,cosmetics box, moon cake box, electronic product box, calendar, etc.

| Model | JG-FMLD780A |

| Max Cover Size | L780×W450mm |

| Min.Cover Size | L200×W85mm |

| Max. Paper Size | L820×W490mm |

| Min. Paper Size | L240×W125mm |

| Board Thickness | 1.0-3.0mm |

| Paper Thickness | 120-300g |

| Speed | ≤40 pcs/min |

| Precision | ±0.10mm |

| Detecting System | advanced laser photoelectric system |

| Boards Amount | 1-5 Pieces |

| Heating Power | 18Kw |

| Total Power | 55Kw |

| Machine Size | L10000×W5000×H1850mm |

| Machine Weight | 15T |

Note: Due to the continuous improvement of products, the technical data are subject to change without notice.

Sample:

GET A QUOTE

export@86jg.com