Automatic hard cover case making machine is a piece of equipment used to make protective covers for books and other items.Automatic book box assembly machine is used for book box assembly, flat glue drawing, automatic suction plate, and automatic box fixing.

|

Model |

JG-FM700 |

|

Max. Paper Size |

L420×W740mm |

|

Min. Paper Size |

L120×W260mm |

|

Max. Cover Size |

L390×W700mm |

|

Min. Cover Size |

L85×W220mm |

|

Board Thickness |

1.0-3.0mm |

|

Paper Thickness |

157-275g/m2 |

|

Speed |

≤40 pcs/min |

|

Precision |

±0.15mm |

|

Detecting System |

advanced laser photoelectric system |

|

Boards Amount |

1-6 Pieces |

|

Min. Spine Width |

10mm |

|

Total Power |

21Kw |

|

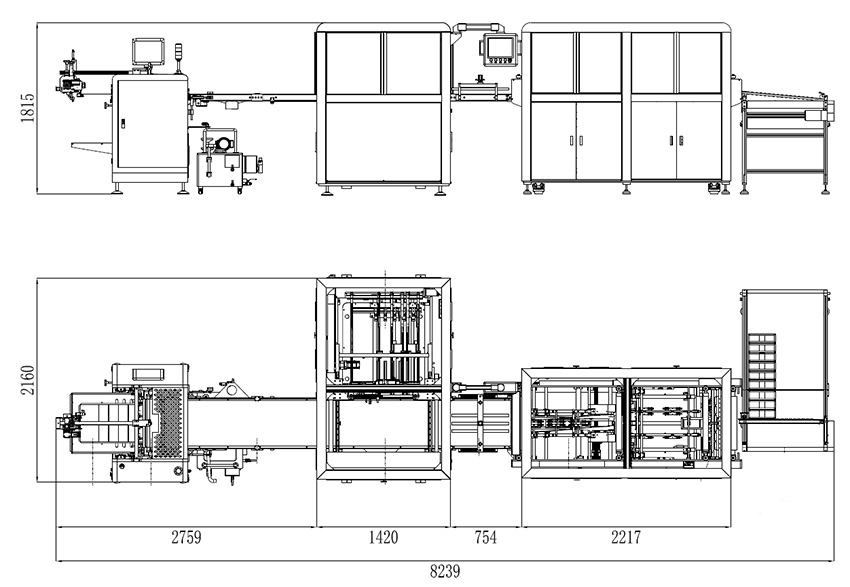

Machine Size |

L8300×W2100×H1800mm |

|

Machine Weight |

4.6 T |

Remark:

1.The Max. and Min. size of the covers are subjected to the sizes and quality of the paper;

2.The speed of the machine depends on the cover sizes and the material and quality of paper and board;

Sample:

Tags:Automatic Hard Cover Case Making Machine,Multifunctional Automatic Case Making Machine,Book Case Making Machine,Full Automatic Case Making Machine

1.Feeder Part:Servo-driven mechanical structure to ensure paper feeding stability and paper feeding speed; Paper loading with 500mm height, reducing the number of downtimes during machine operation. |

|

2.Glue System:The glue system can select white glue or hot glue. When selecting hot glue, a glue viscosity meter is also equipped. And drying unit is equipped for white glue system. The environmental requirements for glue use are low. |

|

3.Positioning Part:Advanced laser photoelectric identification system, to ensure ±0.10mm positioning accuracy and 40 pcs/min speed. |

|

4.Wrapping Part:The combination of horizontal mechanical type and vertical belt type packaging ensures that the packaging edges are firm and flat, and the packaging corners are nice. |

|

5.Collection Part:Adopt intelligent palletizing, so can reduce labor intensity. |

|

GET A QUOTE

export@86jg.com